Our Products

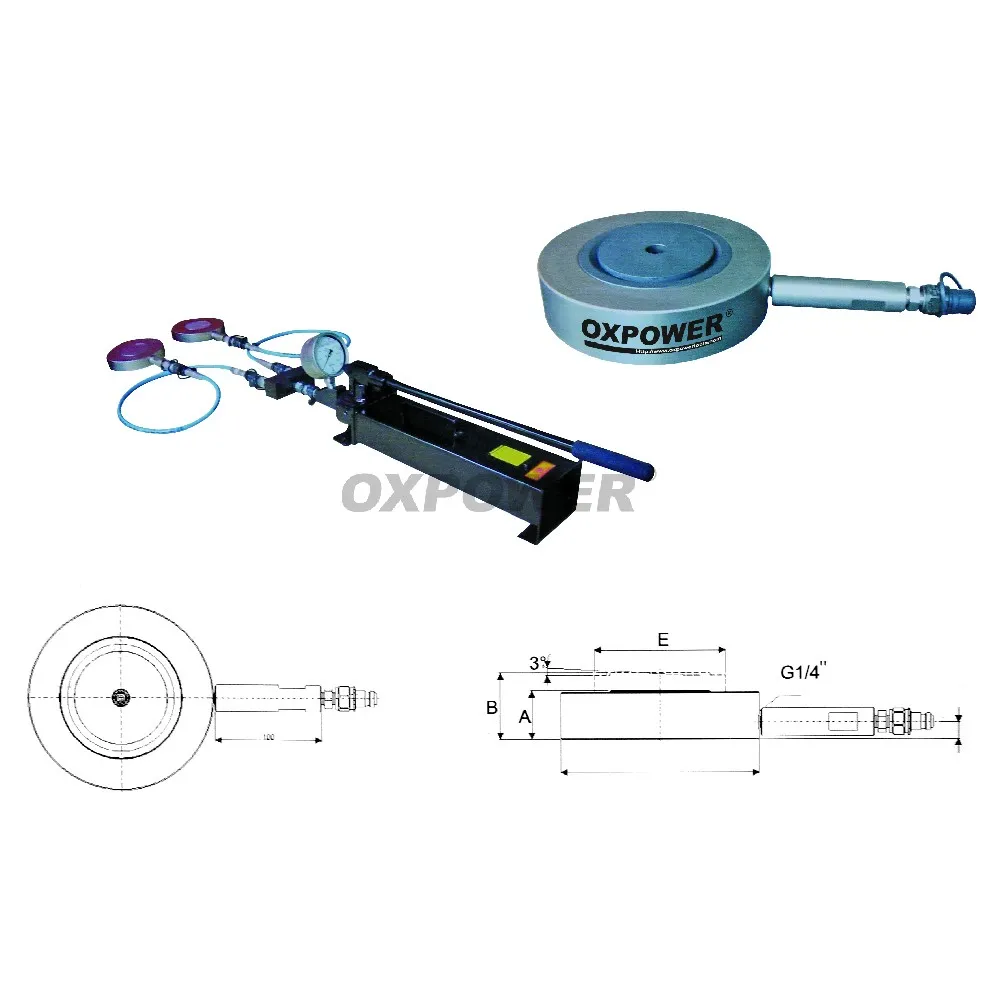

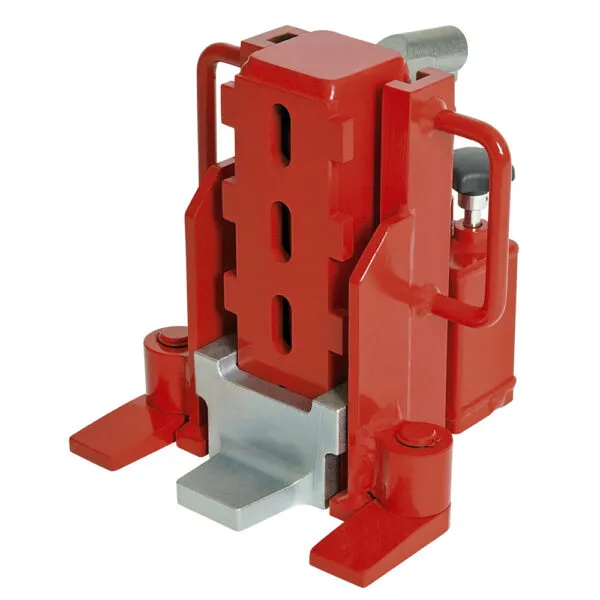

Hydraulic cylinders and jacks

Oxpower Tools is one of the leading manufacturers of various hydraulic cylinders and jacks in China. We provide all types of jacking and lifting solutions directly to customers worldwide at factory direct prices and excellent quality. Our hydraulic cylinders can be used for lifting, pushing, pulling, bending or holding applications in most industrial and commercial work environments. Niu Li Tools offers hundreds of hydraulic cylinder configurations in terms of capacity and stroke, ranging from 4 tons to 2000 tons and strokes from 10 mm to 2000 mm.

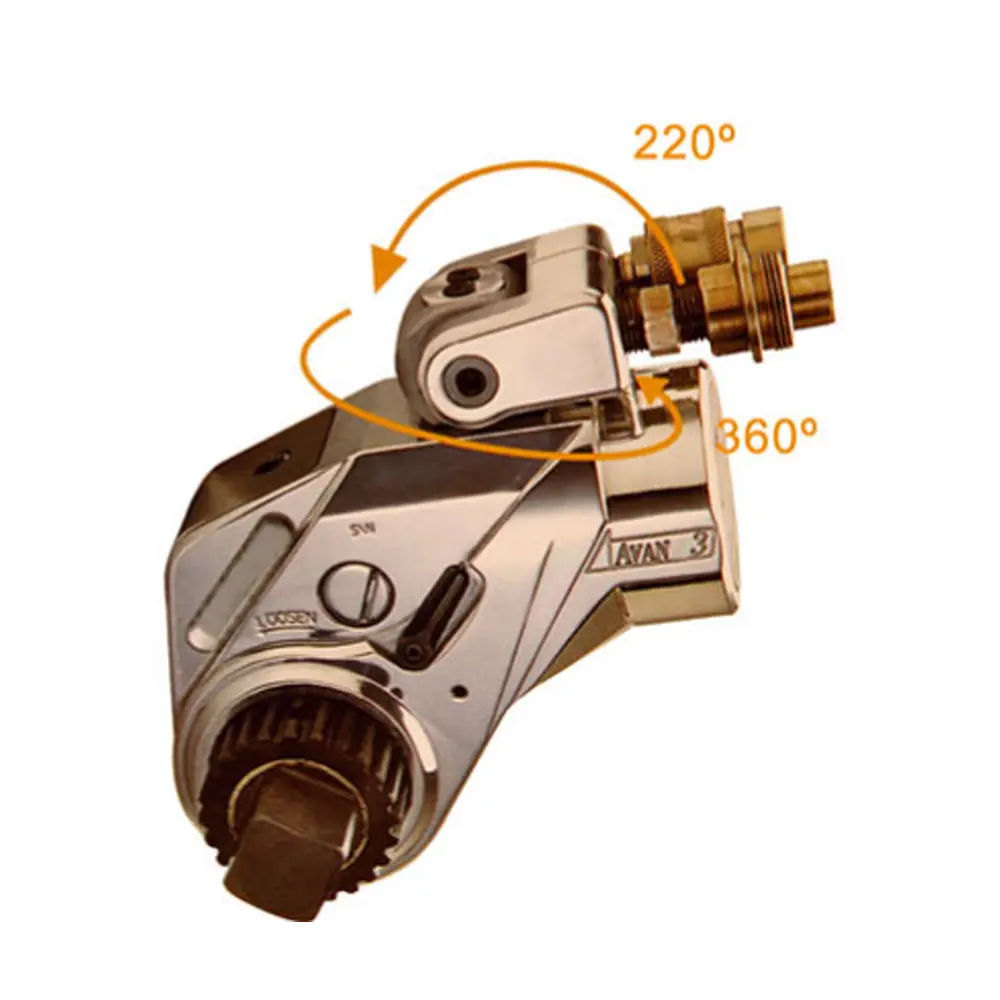

Bolt Tools

Newton Tools offers a wide range of hydraulic torque wrenches, torque multipliers, hydraulic nuts, bolt tensioners and hydraulic power units for a variety of bolting applications.

Flange maintenance tools

Comprehensive range of hydraulic and mechanical alignment tools, hydraulic nut splitters, hydraulic flange pullers, and a wide range of mechanical and hydraulic spreading tools for breaking apart stubborn joints.

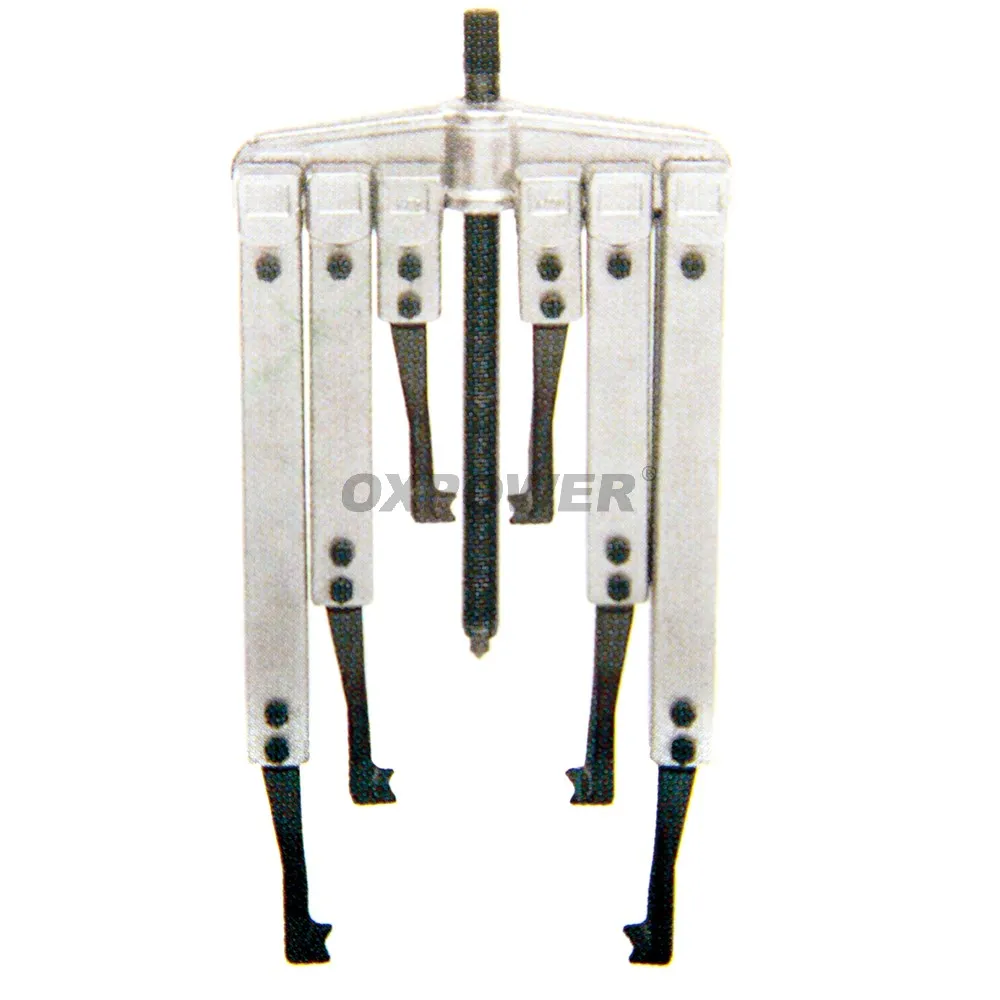

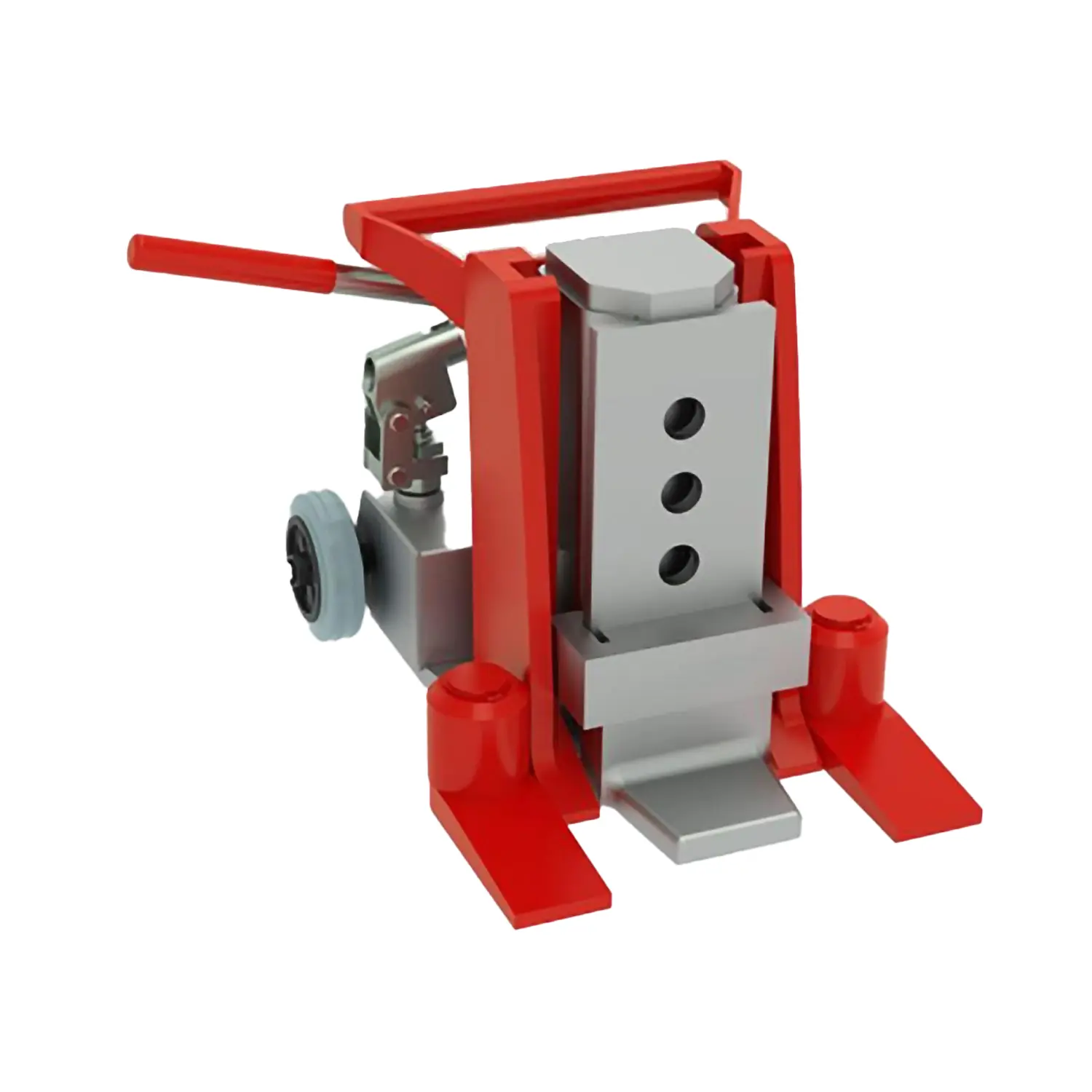

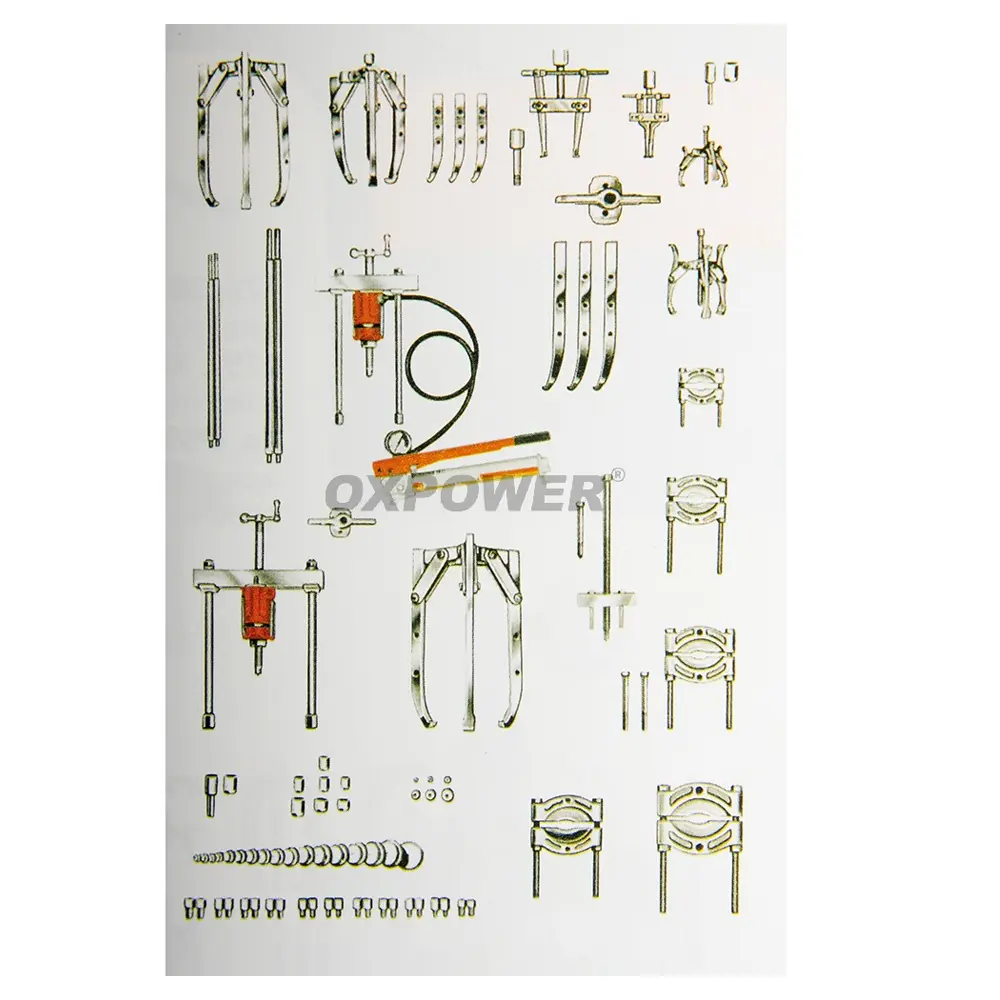

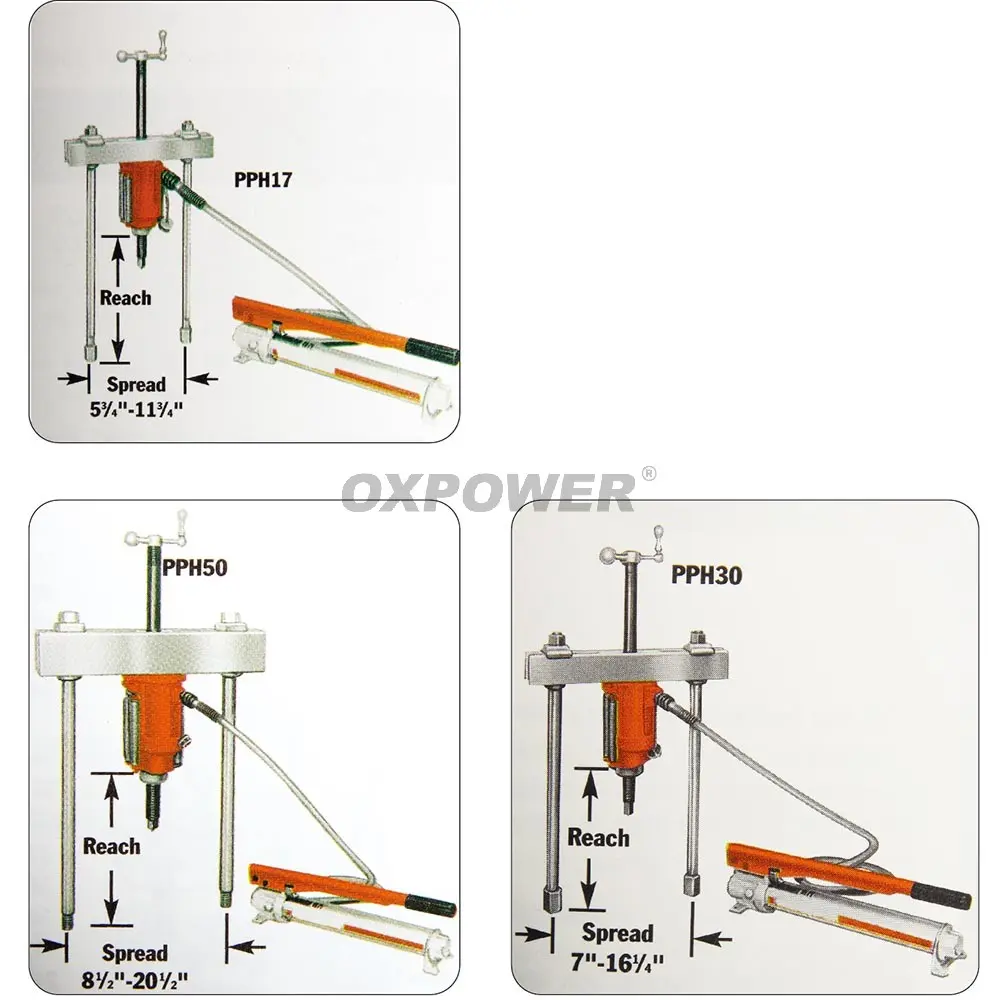

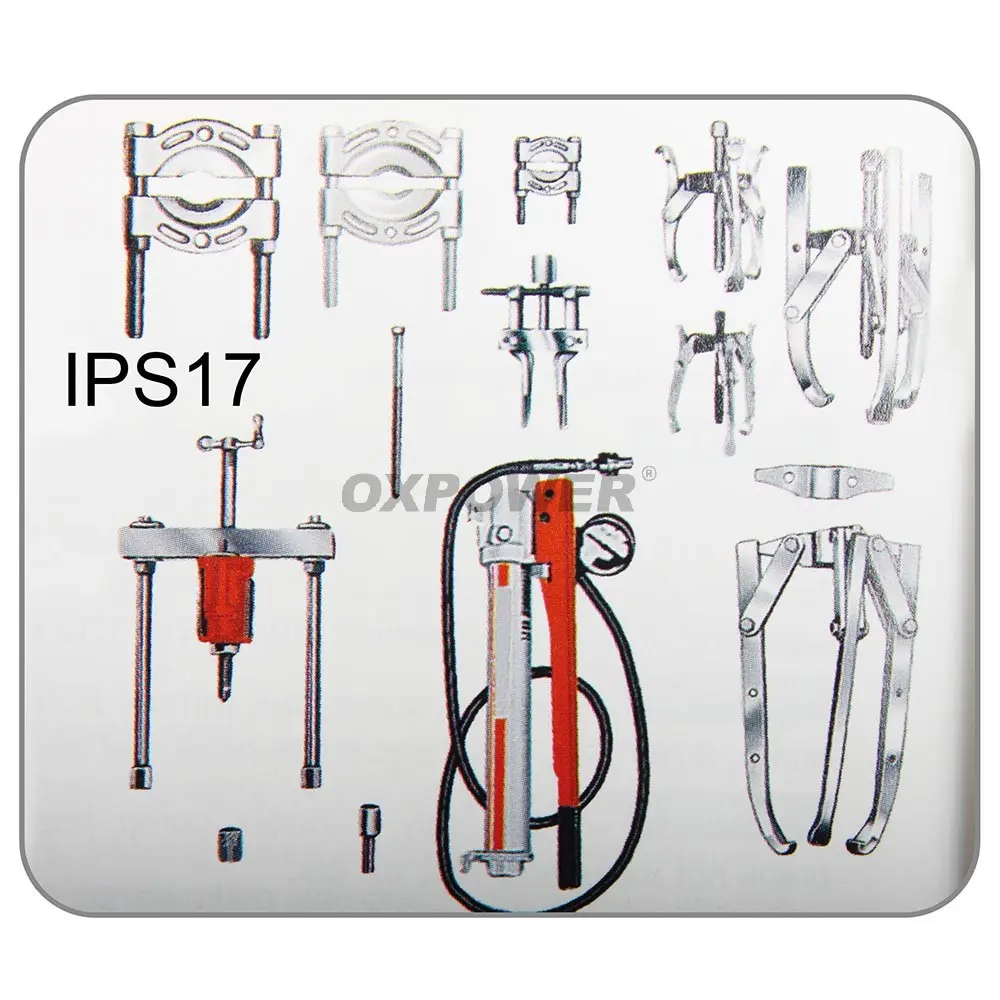

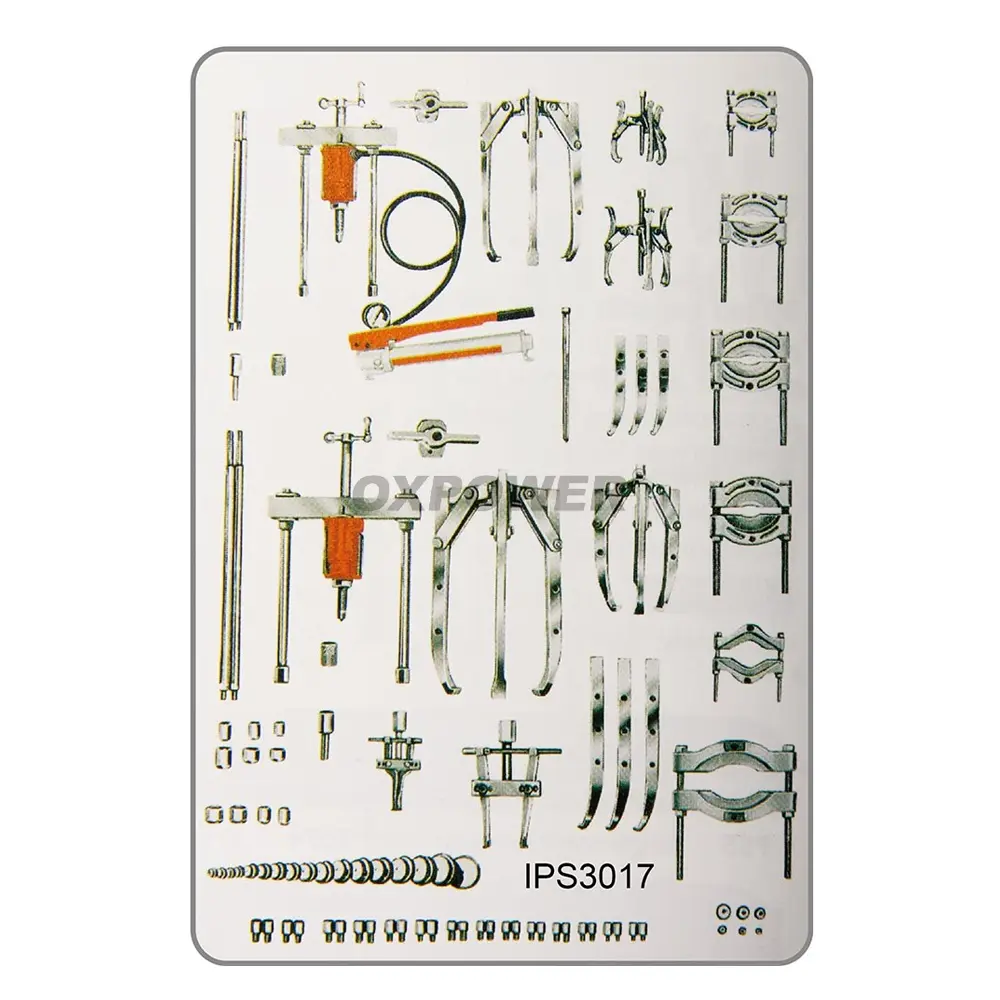

Hydraulic and mechanical pullers

Hydraulic and mechanical pullers are used to remove shaft mounted parts (bearings or couplings). The capacity of hydraulic and mechanical pullers from Newton Tools ranges from 2 tons to 600 tons. In addition to railway vehicle maintenance, machinery installation, mine maintenance, construction support, it can also remove round workpieces such as pulleys, gears, bearings, etc. in various mechanical equipment.

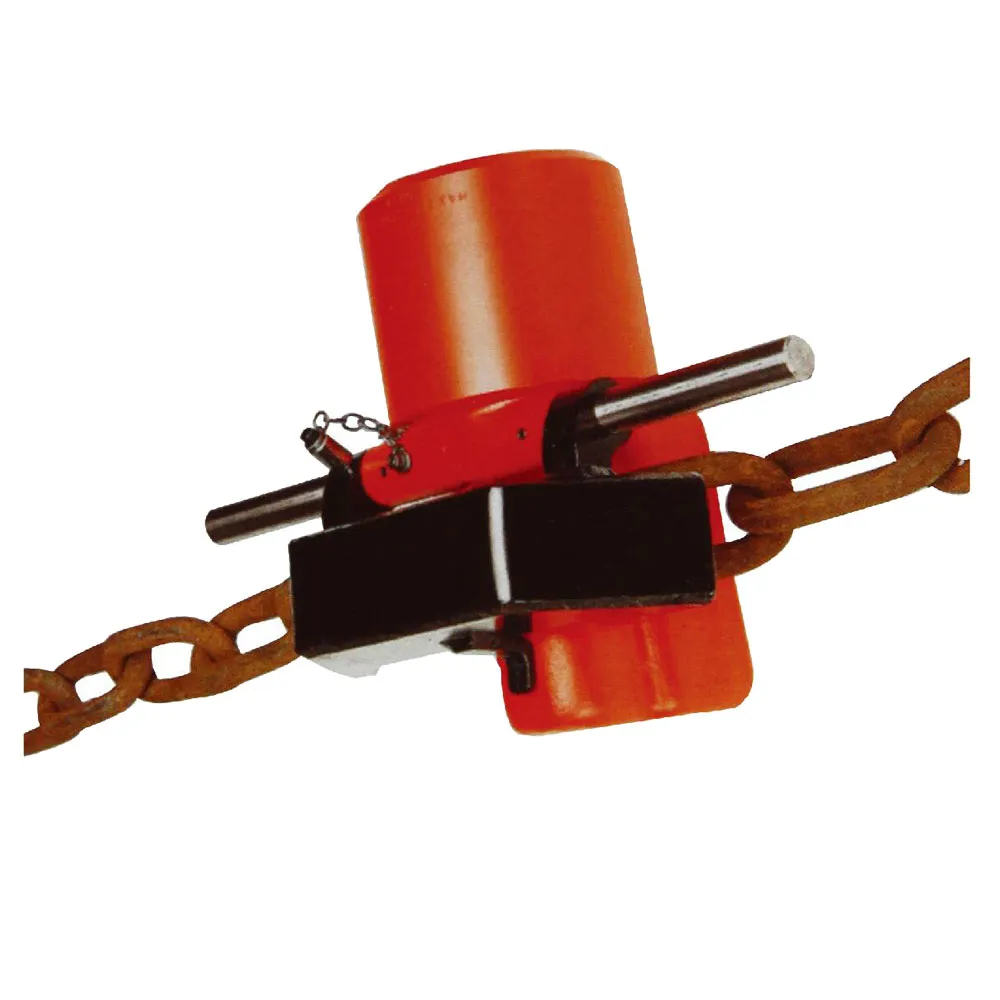

Hydraulic cutters and crimping tools

When you need to cut heavy bars, chains, cables, nuts and similar materials, or if you need to find the right crimping tool, you need look no further than Newton Tools’ wide range of cutters and industrial presses.

Hydraulic pumps and power units

Newton Tool Hydraulic Power Units are available in a variety of different configurations. Whatever performance, speed, control, intermittent or heavy-duty performance your high pressure pump requires, you can be sure we have the right hydraulic power unit for the application. Available in manual, electric, air and gasoline powered models with multiple reservoir and valve configurations.

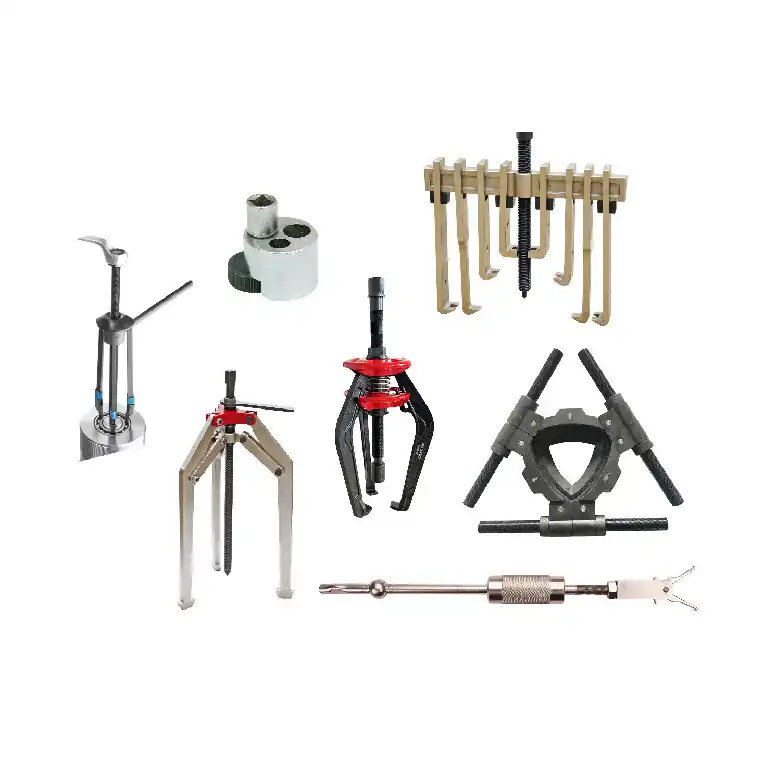

Auto Maintenance Tools

OXPOWER Tools offers a wide range of non-standard bearing repair and automotive maintenance tools in a variety of sizes, capacities and styles. Whether your application requires mechanical or hydraulic, OXPOWER can meet your needs. Made of high-strength alloy steel, the puller can provide years of trouble-free operation even in the harshest environments, and you can rely on it.

Hydraulic accessories

A line of hydraulic accessories including quick connectors, adapters and distributors, pressure gauges and adapters, fittings and diverter manifolds, safety valves, pressure regulating valves, check valves and flow regulating valves, directional control valves, hoses and pressure sensors for reliable fluid power system integration and performance in all industrial machinery.

For business use

Widely used in pipeline maintenance, pipeline construction, testing and flange replacement, maintenance gaskets, pressure vessels, cylinder head opening, power plants, bearing removal, oil and power drilling, motor rotor removal, offshore platforms, jacking work, shipbuilding, industrial equipment, horizontal movement of workpieces and other industrial applications.

Blog

How does a hydraulic press work?

A hydraulic press is a machine with a bed or plate in which objects (usually made of metal) are placed so that they can be easily crushed, straightened, or shaped. The original concept of a hydraulic press was based on Brayspascal's Law. This law states that when pressure is applied within a closed system, the pressure throughout the system remains constant. A hydraulic press can essentially be explained as a machine that uses a hydraulic system, including a hydraulic pump and cylinders, to crush something. How does a hydraulic press work? The working principle of a hydraulic press is very similar to that of a standard hydraulic system. A hydraulic press consists of the same components used in a hydraulic system, including a hydraulic pump, cylinders, pistons, and tubing. The press system consists of two cylinders. Fluid is poured into a cylinder with a diameter much smaller than its counterpart; this smaller cylinder is called the driven cylinder. The piston in this cylinder is pushed, thus compressing the fluid, which then flows through tubing into the larger cylinder. The master cylinder (larger) then pushes the fluid back into the original cylinder. What are the uses of a hydraulic press? The hydraulic motor and driven mechanism apply force to the fluid. The cylinders generate a greater force when compressed into the master cylinder. Hydraulic presses are primarily used in industrial applications, requiring significant pressure to compress materials (usually metal) into large sheets. The basic description of a hydraulic press is to transform metallic objects into sheets. In some industries, it's used for thinning glass, manufacturing cosmetic powders, and medical tablets. Hydraulic presses can meet the needs of a variety of industries. For example, in the landfill industry. A hydraulic press is the core of any car shredding system. In this process, a hydraulic motor applies significant pressure to fluid already in a cylinder. This pressure causes the sheet to rise, and with such great force behind it, the sheet is pushed onto a car, which crushes it. Another application of hydraulic presses is for crushing scrap from cars, equipment, or machinery; therefore, the price of hydraulic presses can vary. Below are our images showcasing H-frame hydraulic presses and roll-up hydraulic presses.

What is a pile static load test?

Static load tests on piles are used to measure the behavior of piles under known loads. A static load test involves applying a constant static load (Kentridge) to the top of the pile. The load is gradually increased. Piles are typically not tested for their full design capacity, but rather for a small portion of the design load. The resulting displacement is measured and compared with the applied load to verify the pile's geotechnical properties, including: The standard arrangement and sequence of a static load test for piles is as follows: 1. Pile foundation construction 2. A hydraulic cylinder is installed on the pile head 3. A primary and secondary steel beam trellis is erected above the jacks to support the static load 4. A reference bar is established near the pile and the hydraulic jacks to provide a reference point for measuring settlement after pile compression 5. Sufficient static load is applied to the trellis system. The load is predetermined by the structural and geotechnical engineers. The static load can be provided by any material such as bricks, concrete blocks, or sandbags. 6. The hydraulic jacks are pressed against the pile head and the underside of the trellis main beams. The hydraulic jacks gradually expand, causing the load to gradually increase from the static load trellis to the pile head. 7. With each increase in load, the settlement of the pile is measured using a benchmark rod as a reference. This can be extrapolated later to verify the full design load on the pile. The diagram below shows a cross-section of this typical arrangement… New Power Tools has a product for this test: the 2500-ton RR series hydraulic cylinder. Made of high-alloy steel with a robust exterior paint finish, it can withstand the most demanding applications. Advanced seals and chrome-plated piston plungers contribute to extended service life. The double-acting center-bore hydraulic cylinder has two connection ports, providing hydraulic flow for the advance and retraction of the plunger. This provides more controlled retraction than a single-acting cylinder.

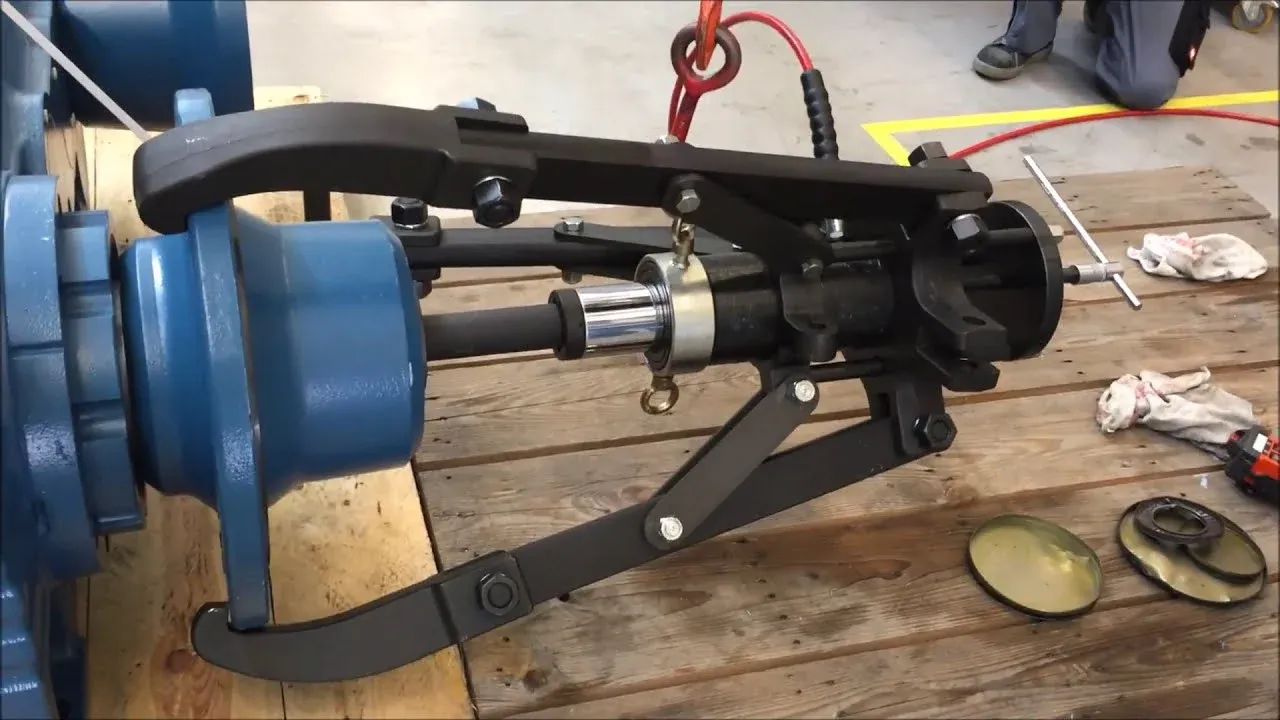

How does a hydraulic bearing puller work?

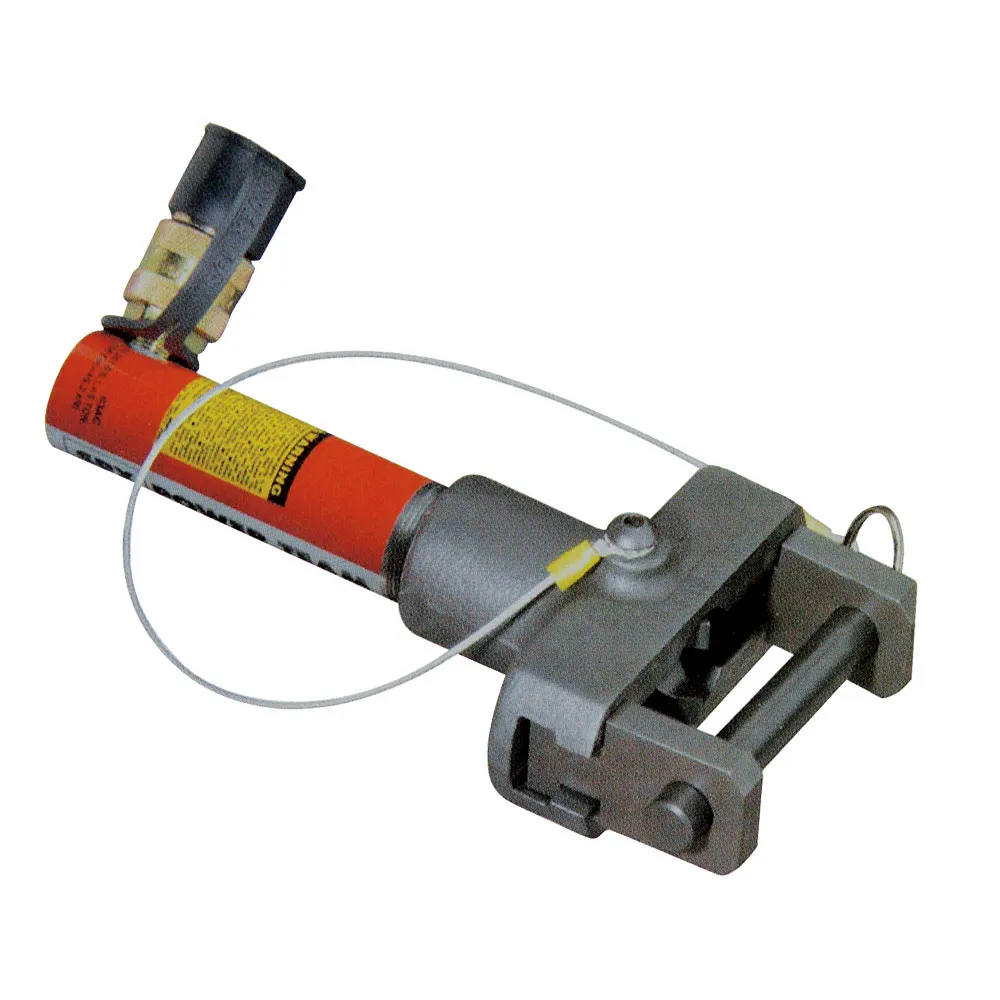

Hydraulic bearing pullers utilize a hydraulic actuator to move the hydraulic lever directly forward, so the lever itself does not rotate. The hook seat can be adjusted directly with the line to change its distance. During operation, simply swinging the handle slightly back and forth causes the hydraulic actuator to move forward and backward accordingly, pulling out the object. Bearing Removal: Using a bearing puller to remove bearings is particularly inexpensive, but its disadvantage is that careless operation may scratch the shaft. Due to differences in mechanical mechanisms and drive power, pullers can be divided into hydraulic pullers and mechanical pullers, as well as two-jaw pullers and three-jaw pullers. Before removing bearings, choose the appropriate type of puller from a puller manufacturer with sufficient capacity to complete the task. How to Use a Hydraulic Bearing Puller? Hydraulic pullers are divided into small and heavy-duty types. For information on how to use a small hydraulic puller, please read the following article. This article mainly introduces the NiuLi Tools heavy-duty hydraulic puller, with a pulling capacity between 50t and 300t. Using a heavy-duty hydraulic puller typically involves several steps: Preparation: Ensure the puller is in good working condition and that all necessary safety precautions are in place. This includes wearing appropriate personal protective equipment (PPE), such as gloves and safety glasses. Positioning: Move the gear puller to the location where the gear needs to be removed. The wheels at the bottom of the puller allow for easy movement and positioning. Connection: Securely connect the puller arm or jaws to the gear to be removed. Ensure the connection point is secure and properly aligned with the gear. Hydraulic Setup: Connect the hydraulic pump to provide power to the hydraulic bearing puller and set the pressure gauge. Applying Pressure: Activate the hydraulic system to apply pressure to the puller. This will generate a force that gradually pulls the gear away from the shaft or mounting. Monitoring: Closely monitor the pulling process to ensure it is smooth and safe. Check for any resistance or signs of adhesion that may indicate a problem. Pulling Out: Once the gear has been fully pulled away from its position, stop the hydraulic pressure and carefully remove the gear from the shaft or mounting. Avoid sudden movements that could cause injury or damage. Safety: After completing the gear removal task, store the gear puller in a safe location until needed again. When using a hydraulic bearing puller, always follow the manufacturer's product instructions and guidelines to ensure safe and effective operation. In addition, proper training and experience are also important for operators.

What is an intelligent PLC electric hydraulic pump?

A smart PLC electric hydraulic pump is a hydraulic pump system with an integrated programmable logic controller (PLC) for advanced control and automation. This integrated system precisely controls hydraulic pressure, flow, and other parameters, improving efficiency, accuracy, and safety in a variety of applications. Here's a more detailed explanation:

Features of Electric Torque Wrench Pump

In today's fast-paced industrial environment, achieving precise and reliable bolt tightening is crucial to ensuring the reliability and safety of buildings and machinery. Traditional manual bolting techniques can provide uneven torque application, leading to equipment failure and safety risks. Electric-hydraulic torque wrench pumps have emerged as a reliable and effective solution to these problems. This electric-hydraulic torque wrench pump provides reliable power for precise torque application in a compact, efficient design. A small, transportable device called an electric-hydraulic torque wrench pump is used to power hydraulic torque wrenches in commercial bolting operations. A hydraulic pump with an electric motor provides controlled hydraulic pressure to the torque wrench. The torque wrench then rotates while precisely tightening nuts and bolts using high-pressure hydraulic fluid. Torque pressure monitoring: The torque wrench is powered by a high-pressure hydraulic pump with a highly efficient three-stage flow pressure design. This ensures a steady flow of hydraulic pressure for precise and consistent torque application. Users can set and maintain a specified torque value using the torque wrench pump's built-in pressure control system. This feature ensures controlled tightening and prevents overtorque, reducing the risk of component damage. Many modern electro-hydraulic torque wrench pumps feature a user-friendly digital display, allowing operators to monitor pressure, torque values, and other important parameters. Motorized hydraulic torque wrenches. Electro-hydraulic torque wrench pumps offer unparalleled bolt tightening accuracy. They enable users to consistently achieve precise torque levels, ensuring uniform bolt tension across all fasteners. Compared to manual bolting, electro-hydraulic pumps significantly reduce the time required to apply torque. Automated operation and quick setup save critical time during the bolting process. Pressure control systems and digital pump monitoring reduce the risk of damage to bolts, nuts, or equipment, preventing over-torque. Ensuring Product Integrity: This pump tightens large bolts in heavy equipment used in steel structures, bridges, and construction projects. Component assembly in industrial processes depends on pumps, where precise and consistent torque is crucial to product integrity. Pumps ensure the proper assembly of wellheads, pipelines, and other critical components in the oil and gas sector. Turbines, generators, and other power generation machinery use electro-hydraulic pumps for maintenance and servicing. Improving Industrial Bolting Efficiency: Electro-hydraulic torque wrench pumps have revolutionized industrial bolting. This technology has evolved to become an essential tool across many different industries. It provides precise torque application, time savings, improved safety, and portability. As technology develops, we can expect more improvements in electric hydraulic pumps, bolting process optimization, and overall industrial efficiency.

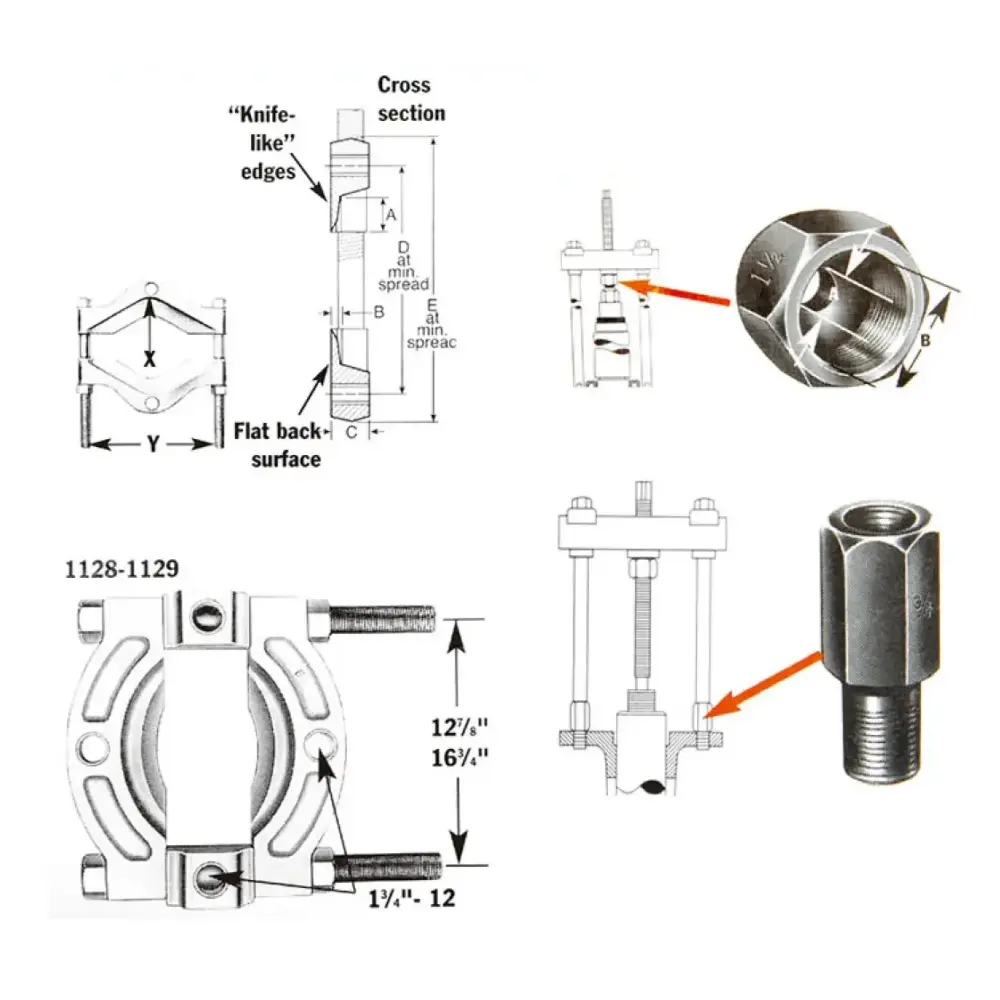

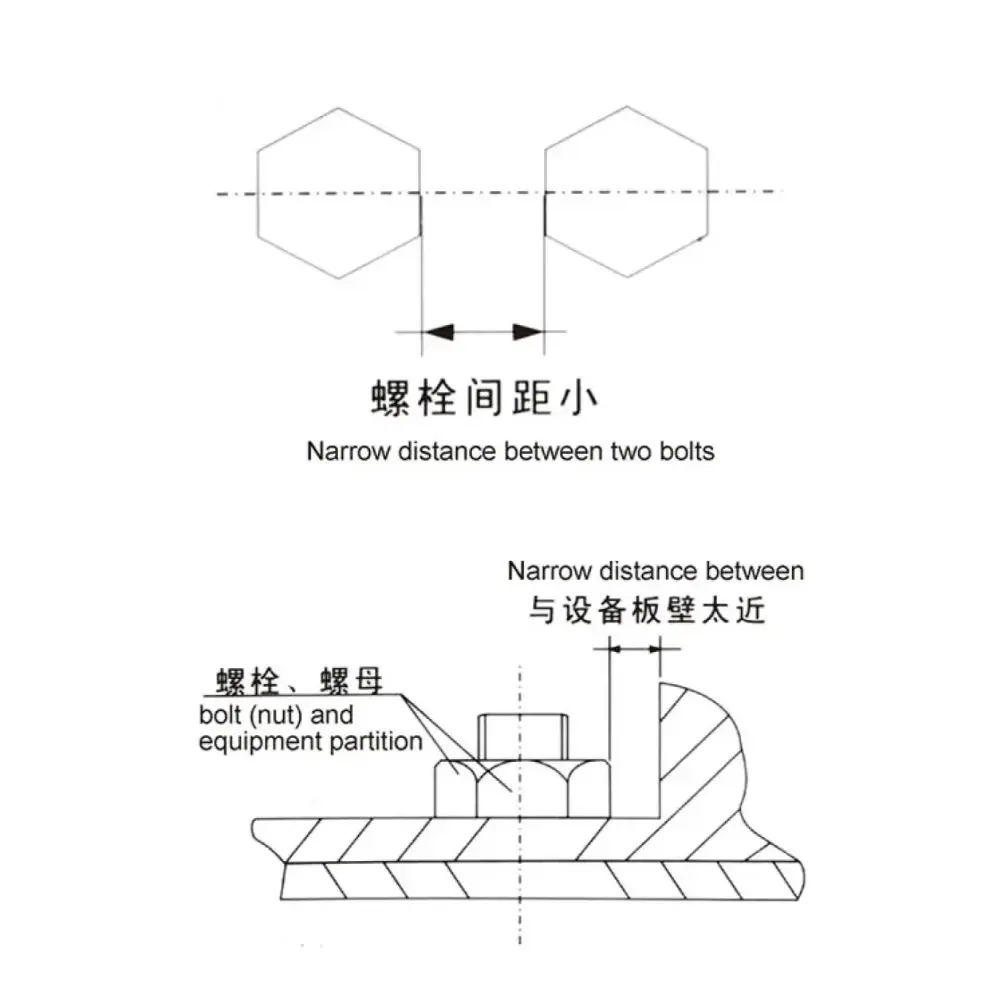

What is a Hydraulic Nut Splitter?

Specialized tools and equipment are essential in industrial maintenance and machinery repair. The hydraulic nut splitter is one such tool that plays a vital role in disassembling and repairing heavy machinery. The purpose of this article is to give readers a comprehensive understanding of hydraulic nut splitters, including their definition, uses, and importance in various fields. Basics of Hydraulic Nut Splitter To remove rusted or over-tightened nuts from bolts and studs, use a hydraulic nut splitter, a sturdy and precisely constructed tool. These nuts are frequently used in high-stress environments such as bridges, pipelines, factories, and large machinery. Traditional methods of nut removal, such as wrenches or torches, can be time-consuming and risky. Hydraulic nut splitters offer a safer and more efficient alternative. How do hydraulic nut splitters work? Hydraulic nut splitters and their cousins Hydraulic nut splitters operate on hydraulic pressure. They consist of a hydraulic pump, a high-pressure hose, and a cutting head. The pump generates tremendous hydraulic pressure, which is transmitted through the hose to the cutting head. The cutting head, equipped with a hardened steel blade, is positioned over the nut to be removed. When activated, the hydraulic pressure forces the edge to close on the nut, resulting in a clean, precise cut. This fast, efficient process minimizes damage to the bolt or stud. Advantages of Using a Hydraulic Nut Splitter Precision and Safety: Hydraulic nut splitters offer precision that cannot be matched by traditional methods. This precision ensures that the bolt or stud remains intact and undamaged during the nut removal process. Time Efficiency: The speed at which hydraulic nut splitters work significantly reduces downtime during maintenance or repair operations. In industries where maintaining machinery uptime is critical, maintaining machinery uptime can result in significant cost savings. Versatility: Hydraulic nut splitters are versatile tools that are capable of removing nuts of various sizes and materials. They are suitable for nuts made of steel, stainless steel, aluminum, and other materials, making them an indispensable tool across several industries. Reduced Physical Stress: Operating a hydraulic nut splitter requires less physical effort than a manual wrench. As a result, worker fatigue may be reduced and the workplace will be safer. In summary, hydraulic nut splitters are indispensable in a variety of industries, providing precise, efficient, and safe results when removing nuts from bolts and studs. Their applications are varied, from construction to aerospace, and choosing the right tool is essential to achieve optimal performance. As the demands placed on machinery across industries continue to increase, hydraulic nut splitters are playing an increasing role in maintenance and repair operations, ensuring the longevity and reliability of critical infrastructure and equipment.

Features of Electric Torque Wrench Pump

In today's fast-paced industrial environment, achieving precise and reliable bolt tightening is essential to guarantee the reliability and safety of buildings and machinery. Traditional manual bolting techniques can provide uneven torque application, leading to equipment failure and safety risks. Electric hydraulic torque wrench pumps have emerged as a reliable and effective solution to these problems. This electric hydraulic torque wrench pump provides reliable power for precise torque application in a compact, efficient design. Hydraulic Torque Wrench System A small, transportable device called an electric hydraulic torque wrench pump is used to power hydraulic torque wrenches in commercial bolting jobs. A hydraulic pump with an electric motor is responsible for providing controlled hydraulic pressure to the torque wrench. The torque wrench then rotates as the nuts and bolts are precisely tightened using high-pressure hydraulic oil. Monitoring Torque Pressure The torque wrench is powered by a high-pressure hydraulic oil hydraulic pump with an efficient three-stage flow pressure design. It guarantees a steady flow of hydraulic pressure for precise and consistent torque application. Users can set and maintain a specified torque value using the torque wrench pump's built-in pressure control system. This feature ensures controlled tightening and prevents overtorque, reducing the risk of component damage. Many modern electric hydraulic torque wrench pumps come with a user-friendly digital display that enables the operator to monitor pressure, torque values, and other important parameters. Motorized Hydraulic Torque Wrench The electric hydraulic torque wrench pump provides unmatched bolt tightening accuracy. It enables the user to consistently achieve precise torque levels, guaranteeing uniform bolt tension across all fasteners. Compared to manual bolting, the electric hydraulic pump significantly reduces the time required to apply torque. Automated operation and quick setup save critical time during the bolting process. Pressure control systems and digital pump monitoring reduce the risk of damaging bolts, nuts, or equipment, preventing over-torque. Ensure Product Integrity The pump tightens large bolts in heavy equipment in steel buildings, bridges, and construction projects. The assembly of components in industrial processes depends on pumps, where precise and consistent torque is critical to product integrity. Ensure proper assembly of wellheads, pipelines, and other important components in the oil and gas sector. Turbines, generators, and other power generation machinery use electric hydraulic pumps for maintenance and care. Improve Industrial Bolting Efficiency The electric hydraulic torque wrench pump is revolutionary in industrial bolting. The technology has evolved to the point where it has become an essential tool in many different industries. It provides precise torque application, time savings, improved safety, and portability. As technology develops, we can expect more improvements in electric hydraulic pumps, bolting process optimization, and overall industrial efficiency.

What is a reliable flange separator?

The 24 ton hydraulic flange spreader is a heavy-duty industrial equipment that can handle the toughest flange separation jobs. Heavy-duty applications such as large pipelines, pressure vessels and machinery repairs can benefit greatly from its tremendous strength and force. With a load capacity of 24 tons, this hydraulic spreader can apply tremendous pressure to effectively separate flanges, saving the operator time and energy. Its rugged design guarantees longevity and reliability in difficult working environments. Rugged flange spreaders are essential for safe and efficient flange separation in the oil and gas, petrochemical and various manufacturing industries. High-capacity solution for effective and efficient flange separation The hydraulic flange spreader provides a high-capacity solution for industrial activities that require strong force to effectively separate flanges. It outperforms traditional methods, providing greater efficiency and reducing downtime when performing maintenance or repair work. The spreader can use hydraulic power to apply force accurately and evenly, protecting flanges and ensuring smooth operation. Because it uses a forged high-strength wedge-shaped housing, it is recommended for large projects where efficiency and safety are critical. Capability to carry huge loads. With a spreader range of 6-103.5mm, this hydraulic spreader optimizes performance and simplifies procedures across various industrial sectors thanks to its large capacity and user-friendly features. With its unmatched efficiency, this hydraulic flange spreader revolutionizes flange separation. Conventional techniques can require a lot of time and labor, but this hydraulic spreader speeds up the process with its powerful force transmission. Hydraulic pressure is evenly distributed across the flange, minimizing the possibility of vibrations and erratic movements that can cause accidents. Efficiency leads to reduced costs and increased productivity, thus elevating the spreader to the status of an invaluable tool for industrial operations. This hydraulic tool guarantees fast and accurate flange separation every time, whether managing scheduled maintenance or handling emergency shutdowns. Integrated safety features The spreader's non-slip surface and ergonomic handle improve operator control and reduce the risk of accidents during operation. In addition, its solid base and reliable locking mechanism guarantee a safe posture. This hydraulic spreader inspires trust in industry experts, allowing them to work efficiently and safely with peace of mind. Safety is a priority at every stage of development. Superior Industrial Spreader This Hydraulic Flange Spreader is considered the top choice in industrial spreaders and stands out for its superior functionality and performance. Its reputation as a trustworthy and powerful tool has led to it being sought after by professionals in various industries. This hydraulic spreader has become the machine of choice for flange separation and related activities in a variety of environments, including shipyards, refineries, power plants and construction sites. Its real-world application record and satisfied users confirm its position as the first choice to overcome the most challenging industrial difficulties.